After news about an Italian innovation firm Isinnova saving lives by 3D printing ventilator valves for its local hospital, the CEOs, Cristian Fracassi and Alessandro Romaioli, got calls from all over the world.

A lot of 3D printing firms wanted to join and offer their help and some countries wanted to use this tech as well.

However, one of these calls was the start of a completely new project for the staff of Isinnova from Brescia, northern Italy.

Snorkelling Masks & the Coronavirus

Renato Favero is a retired physician who contacted Fracassi and Romaioli through a doctor from the Chiari hospital where they use the ventilator valves.

According to Favero, he was aware of the shortage of CPAP masks for the sub-intensive care patients with COVID-19.

According to the National Heart, Lung, and Blood Institute, these masks are treatments which use a mild air pressure to keep the airways open.

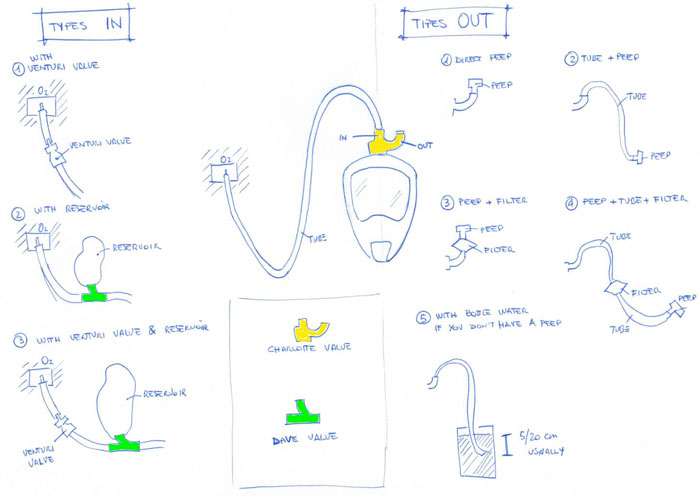

It uses a CPAP machine with a mask or some other device which is placed over the nose and mouth and a tube connects it with the motor of the machine which blows air into the tube.

Romaioli’s and Favero’s Idea: Emergency Ventilator Masks

The engineers proposed making an emergency ventilator mask by using snorkelling masks available to the public.

So, they contacted the French sporting goods retailer, Decathlon, about their Easy Breath Surface Snorkelling mask.

The retailer provided 3D computer design for the mask right away and this helped the team of engineers to evaluate the possible modifications.

Unlike full ventilators which breathe in and out for the patient, these CPAP machines regulate the pressure and oxygen level that enters the lungs.

The project took the engineers three days, according to Romaioli. They analyzed, measured, and 3D printed different options.

They needed to do it fast as it was crucial for saving lives- they didn’t do it as a usual project where you have time for checking out three to four times.

They need to speed the testing up.

The First Testing Done on Romaioli & then Hospital Patients

Romaioli himself decided to test out the mask first- he put it on his head to check out if the adaptations they did were successful.

He is healthy so it wasn’t a real test. So, before they placed it on an ill person, they needed to test it on someone who’s at risk.

After the primary tests, they sent prototypes to the Chiari hospital and the doctors tested the masks on several patients.

They made around 50 of the pieces needed to transform the masks into CPAP machines; however, they also got other 3D printing companies joining them and helped them make around thousand new machines like this.

Other People from the Globe Are Reaching to Isinnova

Isinnova updated their websites and have full info on English and on Italian, including 3D designs and guidance on creating and using the masks-made-breathing-devices.

A lot of volunteers and doctors reached the company, including South Korea, Brazil, and Canada about this redesign.

The feedback has been positive because it can help apply therapy to people that couldn’t be help before.

All hospitals, according to Romaioli, will run out of breathing masks; however, these DIY ones can be there to help.

The duo engineers are product that they did something good, again.

Sources: